Alarm Management

Introduction

- Apply concepts and procedures for improving alarm management

- Assess the performance of your system with a range of improvement techniques

- How to improve and apply Alarm Management techniques

- Evaluate your current operator readiness, state of training and ability

- Consider the opportunities for increased plant performance and safety Learning

Course Objectives

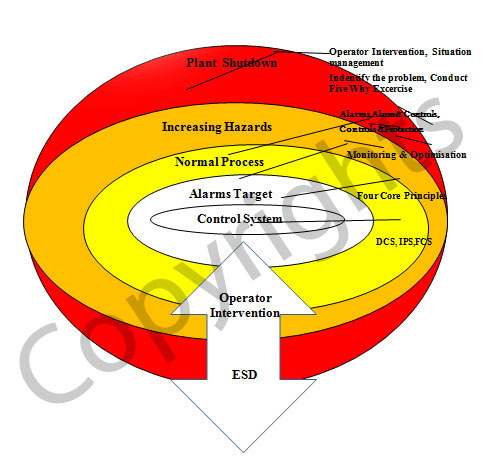

• Alarm Management will provide you with a collection of techniques, tools, standards and procedures that will improve operations and, overall effectiveness

• Business Case Tools: Understand the costs of poor alarm performance or not implementing an alarm management philosophy by reviewing sample business case studies

• Best Practice Alarm Management Strategies: Quickly and effectively integrate alarm management strategies by examining successful, working solutions

• Alarm Management Performance: Understand the number of ways of measuring the performance of an alarm system and its users

• Ensuring that Emergency Response systems are in place so if/when the system does fail the response can be efficient and effective

Training Methodology Delegates will be encouraged to fully participate in this technical programmed through the use of syndicate workshop presentations, group discussions, and workshops. A hard-copy manual, relevant material will be provided. Course explains concepts and procedures in a clear fashion and will include daily summaries, workshops designed so that the delegates can effectively apply the course material in their daily work. The many shortcomings found in alarm systems can cause incidents where the risk to personnel is increased together with an increase in operation costs. Participants will be introduced to concepts, methods and procedures for dealing with alarm management systems. Configured and correctly enforced, alarms need to be set at the right operating conditions identify possible causes for the alarm whether it’s legitimate (providing information), spurious (misleading or a nuisance) or redundant (telling the operator something he already knows) Such conditions will be a major tool allowing process operators to rapidly identify escalating abnormal situations and take action to recover Avoid abnormal situations that can quickly lead to personnel danger, environmental issues, commercial loss and a damaged reputation

Course Benefits

JNAK Oil and Gas Industrial Trainings Programme Shall develop Professional Skills for better Job Opportunities and Candidates Career Enhancement

- Overview knowledge of Oil & Gas Industries Operations

- Improvement of Technical skills and Confidence

- General overview of Oil and Gas industries Process safety Management

- General Awareness in Operational Facilities & Risk management

- Awareness & overview of Fire & Safety and Hazards

- Career Enhancement and job security

- Candidates Engagement with National & International Clients

- Candidates Salary improvement Seniority

Course Outline

- Introduction, Aims and objectives of the course

- Principles of Alarm Management programme

- Measuring performance along with Human Factors

- Self-Evaluation

- Study on major incidents

Course Eligibility

- Control room Operators

- Operation Supervisors

- Instrumentation Maintenance Team Members

- Electrical Maintenance Team Members

- Process Maintenance Team Members

- HSE Team Leaders