Rotating Equipment Engineer

Introduction

Course Objectives

Instrument & Control Engineer course is designed to understand ongoing Construction, Commissioning & Maintenance activities in day-day operations. JNAK training is to enhance the candidate’s technical skills by providing brief knowledge of operating philosophy’s, control narratives, Safeguarding philosophies of Rotatory equipment’s, Instrument & Control Engineer course is design for Rotating Equipment’s engineers, supervisors, Technicians, such as GE Gas Turbines for Gas compressor & Power Generation, Solar Turbines Gas Compressors/Power Generation, IHI Steam Turbines, SULZER steam Turbines /Compressors, Mitsubishi steam Turbines/Compressors, Ingersoll-Rand Reciprocating compressors and booster pumps and control system such as Speedtronics Control system, Yokogawa Centum Cs , Allen-Bradley PLC’s, Siemens PLC’s, Bentley Nevada Machine Monitoring system (Vibration and temperature) IPS &FCS Control System.

Training courses has been designed to share practical knowledge from experience Engineers to develop the candidate’s expertise in process instrumentation calibrations and commissioning procedure of process instrumentation, Loop checking from field to DCS (Distributed control system) marshaling cabinets ,Fire & Safety protection system IPS (Instrumented protective system) cabinets ,Loop checking & Trouble shooting and feedback signal from MCC cabinets for startup sequence checks, DCS feedback signal and commands to verify Startup & shutdown sequence verification, Expertise in Root cause analysis, process safety management, Risk assessment, understanding of Hazardous area classification, SIL (Safety Integrated Level) to understand the logic sequences candidates shall have concrete knowledge to understand the Logic gates functionality and implementation during the commissioning and start-ups Investing valuable time and money for getting professional trainings will keep you update as per the latest technologies and to understanding, the differences between the construction projects, pre-commissioning, Commissioning and facilities maintenances projects

Course Content

- Brief Introduction on HSE

- Brief Introduction Fire & Safety system

- Fire protection system & Safeguarding system

- CO2 Auto Extinguishing system

- Detail Study on Engineering Drawings

- Familiarizations on Operating Philosophy

- Familiarization on Control Narratives

- Plant startup/ Shutdown Safe guarding philosophy

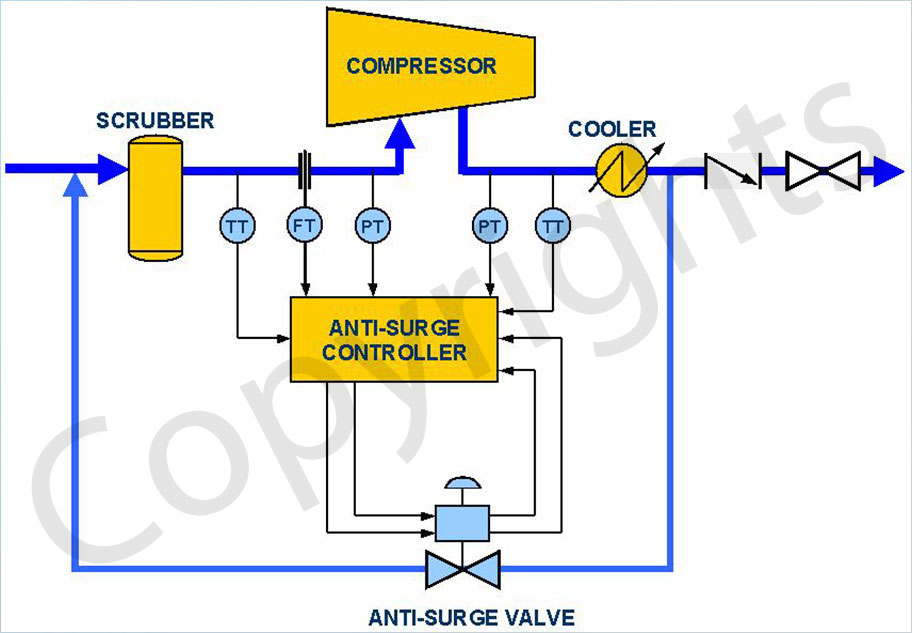

- Compressors Anti-Surge Control System

- ESD (Emergency Shutdown)logics

- Compressors Startup /Shutdown Logic Sequences

- Auxiliary & Lube oil Pumps start-up/Shutdown logic

- Detail study on Control logics Gates and Interlocks

- Commissioning procedures of Process control Loops

- D/P Flow Transmitter’s

- Orifice plates orientation procedures

- Pressure Transmitters

- Temperature Transmitters

- Switches Contacts and feedbacks review

- Details Study on control valves operating philosophy’s

- Control valves Calibration and trouble- shooting procedure

- Machine Monitoring system

Benefits

During training period of JNAK we make sure candidate shall understand field instrument calibration procedures, troubleshooting procedures, loop checking procedures, commissioning procedures etc. these trainings will add value to every individual for best job opportunities as specialized engineer

Who can attend?

- Instrumentation Engineers / Diploma Holders

- Electrical & Electronics Engineers/ Diploma Holders

- Mechanical Engineers Specialisation in Rotating Equipments